A recent image of a reconstructed medieval dwelling had posts with square cut ends. The wood craft looked rustic and basic but I wondered about those cut ends. They would be easily done now-a-days with a chainsaw but would (no pun intended) there be any saws from the middle ages that could produce a log with square cut ends?

Found a great reference by P. d’ A. Jones and E. N. Simons: http://goo.gl/KClVt2

The first saws were likely knapped serrated edges of a long narrow piece of flint or obsidian. An improvement could have been made by mounting (with hoof glue) the obsidian into a wooden frame. From there, individual pieces of flint/obsidian may have been glued in a line along the wood frame.

Copper and bronze knifes existed several millennia BC. Dings in the cutting edge may have been found to be useful for digging into wood or stone. This eventually evolved into a whole series of dings, forming the first sawblade.

Bronze saws gave way to iron. And development languished for centuries until the carbon could be controlled. Probably the introduction of crucible steel (see previous post) allowed the cutting teeth to be formed from high carbon (hard) steel.

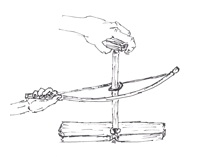

At this point, the “raking” of the teeth developed.

The saws were probably raked to only cut in only one direction (ie. a common pruning saw) as opposed to both directions (a crosscut logger’s saw), since the iron/steel was too soft for cut in a “push” direction.

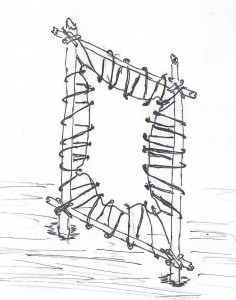

Another development during the Iron Age (500 BC to 50 AD) was the frame saw, which kept the cutting blade under tension so it can be used in both directions (assuming it’s raked in both directions).

According to Jones and Simons, it wasn’t until the 13th century that tapered blades and set teeth were widely used (although set teeth were used by the Romans). The “set” teeth were bent to the side, in an alternative manner, to increase the width of the cut and allowing the removal of cut debris/powder.

In modern times, the quality of steel has given us hand saws of every conceivable size and shape.

So, did medieval dwellings have posts with squared off ends? Probably not, the quality of steel required probably too expensive for most medieval peoples.